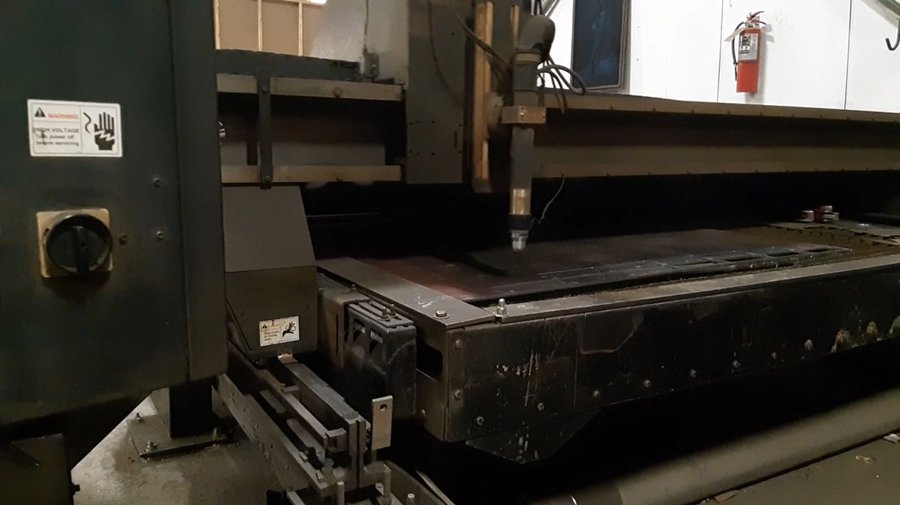

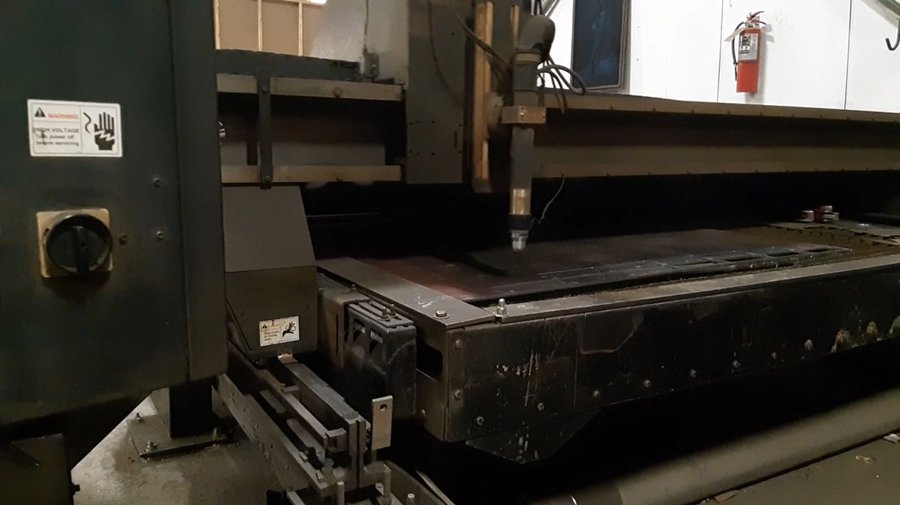

TWS Calgary C&C Plasma Cutting

Plasma cutting is a process that cuts through electrically conductive materials by means of an accelerated jet of hot plasma. Typical materials cut with a plasma torch include steel, stainless steel, aluminum, brass and copper, and other conductive miscellaneous metals may be cut as well.

Used for industrial construction, salvage and scrapping operations. Due to the high speed and precision cuts combined with low cost, plasma cutting sees widespread use from large-scale industrial CNC applications down to small hobbyist.

Basic plasma cutting process involves an electrical channel of super-heated, electrically ionized gas i.e. plasma from the plasma cutter itself, through the work piece to be cut, thus forming a completed electric circuit back to the plasma cutter through a grounding clamp.

The table allows for cutting industrial steel as well all as miscellaneous metals while also effective for decorative design programs.

.